Capability

Early Contractor Involvement

Our in-house design and technical expertise bring value to early involvement collaborations. We work alongside architects, façade consultants and engineers to evolve design concepts into fully considered technical solutions, solving complexity upfront for better informed, more efficient project delivery.

Specialist glass advice

Glass selection can significantly impact thermal performance, aesthetics and project buildability. Our technical expertise in glass type, colour, performance characteristics, and appropriate application can elevate and enable new possibilities for building façades.

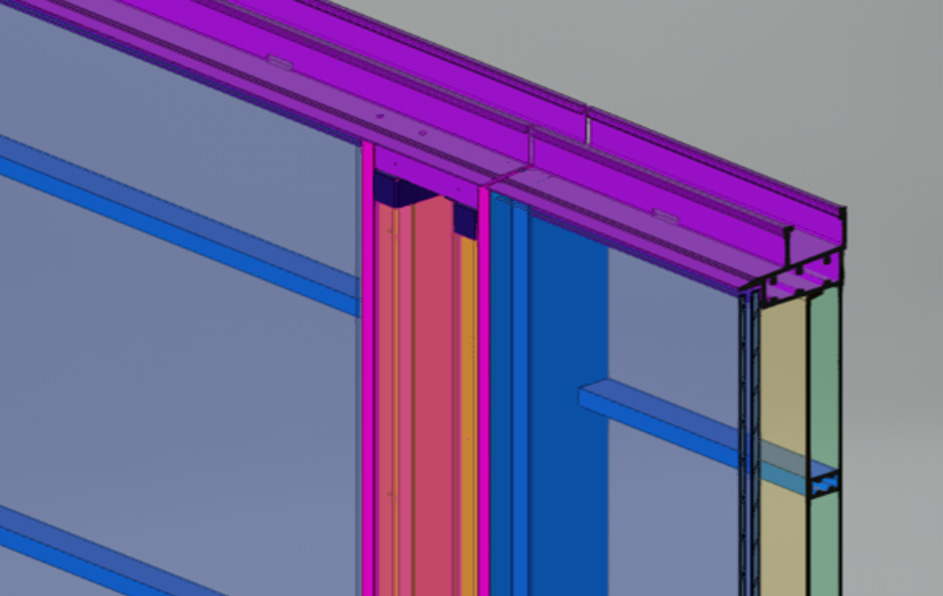

In-house design and shop drawings

We resource design, engineering and technical drawing capability in-house, to ensure a well informed, connected, and responsive design service for our project partners.

Façade features

Our scope and proven capability with facades features continues to grow, as creativity in architecture continues to evolve the possibilities of façade design.

Cladding

An integrated approach to cladding and curtain wall solutions means all aspects of the façade are considered and solved for together, for a more comprehensive solution and reduced risk.

Pre-cast and modular construction

Technical solution design for pre-cast and pre-fabricated panels and modular façade design, bringing installation efficiency and optimised solutions for sites with limited access and space.

Thermal performance and carbon capability

Embodied carbon emissions and building sustainably continues to grow as an industry imperative. We’re proud to be carbon certified, with Environment Product Declarations in place for many of the products we manufacture. Additionally, in early design phase our technical team can help design-in lower carbon, higher performing solutions.