Puhinui Interchange in Papatoetoe underwent a transformative redevelopment in 2020 / 2021 which saw the train and bus terminal completely remodelled and upgraded. Wight Aluminium was engaged early in the design process, and collaborated with Aurecon / Jasmax to develop a façade and glazing solution for the complex station design. The overall form of the building and elaborate, sweeping roofline required an intricately detailed solution for coordinating between the structure and the facades.

With the geometric challenges of the building form, and the many angles and vertices created by the roof design, Puhinui Interchange was one of the most demanding single projects Wight Aluminium has delivered.

The project design phase coincided with NZs first Covid lockdown. To maintain the project timeline, the parties to the technical design solution collaborated remotely and used a 3D digital model to work through each facet of the project. Each interface and connection point between structure and façade was addressed individually, to solve for the geometric challenges of a building where more than half of the facade panels were angled either top, bottom or both, and each of the non-square panels were unique in shape.

The building façade features a raked curtain wall in APL 175 structural glazed suite, with single glazed 13.2mm heat strengthened laminate glass, the largest panels being 1.5m wide and 6m tall.

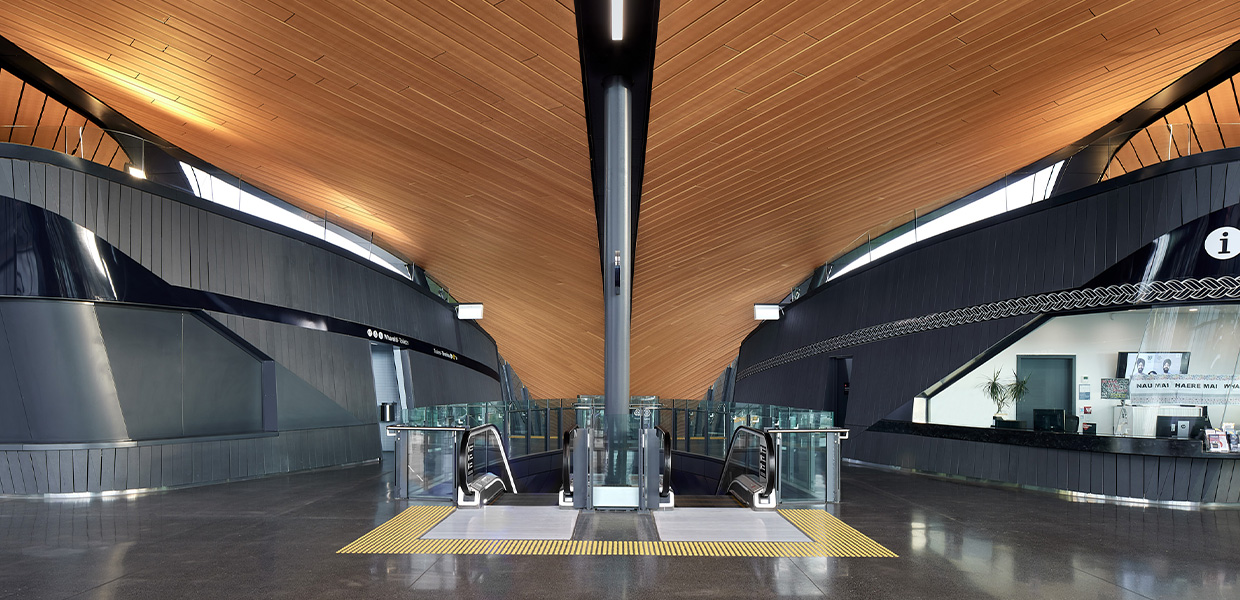

Internally, the station has two pods which serve as ticketing booths and customer service portals. The curved pod frontages transition from being vertical on the sides to sloping on the front – essentially a 3D glass shape. The pod frontages use 17.52mm toughened laminated glass installed in a curved, custom fabricated channel. Windows from the Vantage 40mm suite were also used on the south side of the concourse around the ticket office and administration section.

On the northern side of the building, the upper level façade panels were designed to stop short of the building roof, allowing natural airflow through the top section of the façade, requiring a technically sound installation solution for glass panels supported on only three sides, and with an exposed laminate glass edge. Additional glass performance assessment and engineering consideration was applied to ensure a rigorous solution. The soffit runs through the open-air gap at the top of the facade, transitioning into the interior ceiling, while maintaining sufficient clearance to allow for façade differential movement.